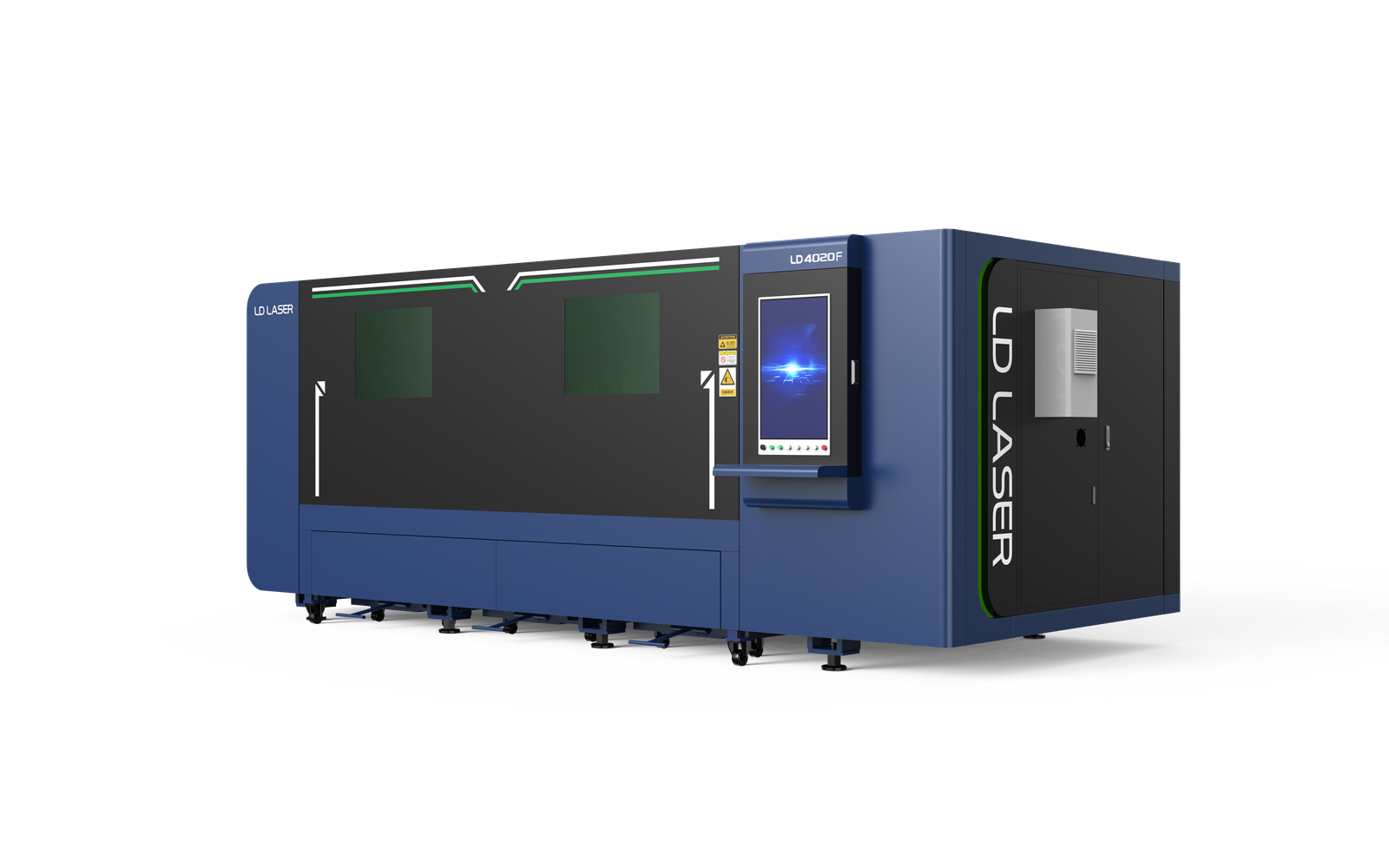

Ultra-high Power Plate Laser Cutting Machine

The upgraded thickened enclosure adopts a fully enclosed structure, ensuring safety and environmental protection. It effectively contains cutting fumes and prevents potential hazards caused by spark splashing. The front-positioned material table facilitates easy maintenance.

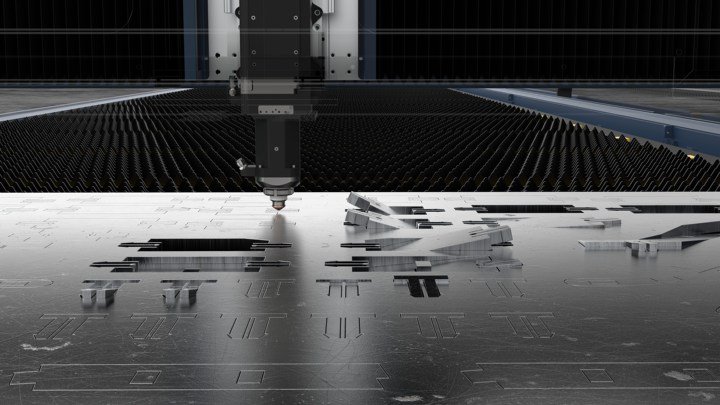

Featuring a dual-worktable configuration, this design enables simultaneous cutting and loading/unloading, significantly reducing idle time. The fully separated work zones (cutting area vs. material handling area) minimize operational risks.

Instant Stop & Auto-Alarm: The machine immediately halts operation upon door opening and triggers an automatic alarm for enhanced protection, ensuring operator safety.

The beam adopts an integrated high-strength steel beam design, tempered to release internal stress, ensuring long-term cutting without deformation.

Processing is optimized to be smarter, safer, more convenient, and more efficient by adapting to real cutting conditions.

The electrical cabinet is integrated with the machine body, occupying a smaller footprint.

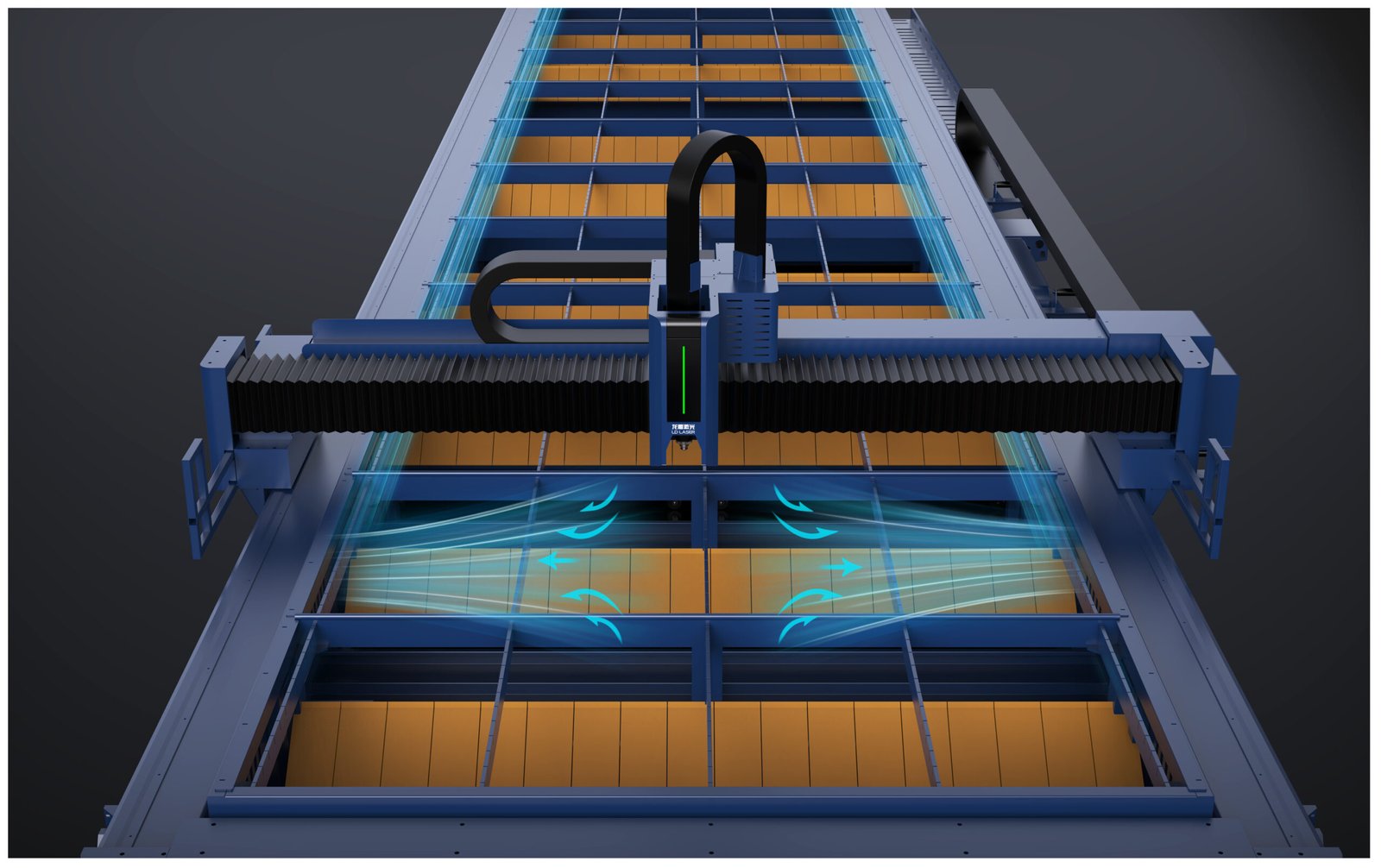

Designed with an extra-large diameter air duct, featuring independent control and zoned dust removal, which improves the smoke and dust removal effect.

Both the loading and unloading tables are equipped with positioning cylinders, ensuring strong stability. The front table is used for cutting while the rear table is used for loading, without affecting the cutting process.

The cutting quality can be judged through the equipment sensors, and the parameters can be adjusted in real time to improve the cutting efficiency and stability.

Based on the actual cutting conditions of the equipment, we can achieve smarter, safer, more convenient and more efficient processing

The ultra-large diameter air duct design is adopted, with independent control and partitioned dust removal to improve the smoke exhaust and heat removal effects

Equipped with ultra-high-definition large-size industrial control screen, equipped with intelligent control system, rich functions, intelligent adjustment, safe production

Through intelligent system monitoring, real-time adjustment of air pressure detection to ensure stable cutting

The equipment features an interconnected dual-screen design, allowing operators to monitor the cutting conditions in real-time while operating the machine.

The equipment is equipped with a new generation (HypCut) smart operating system

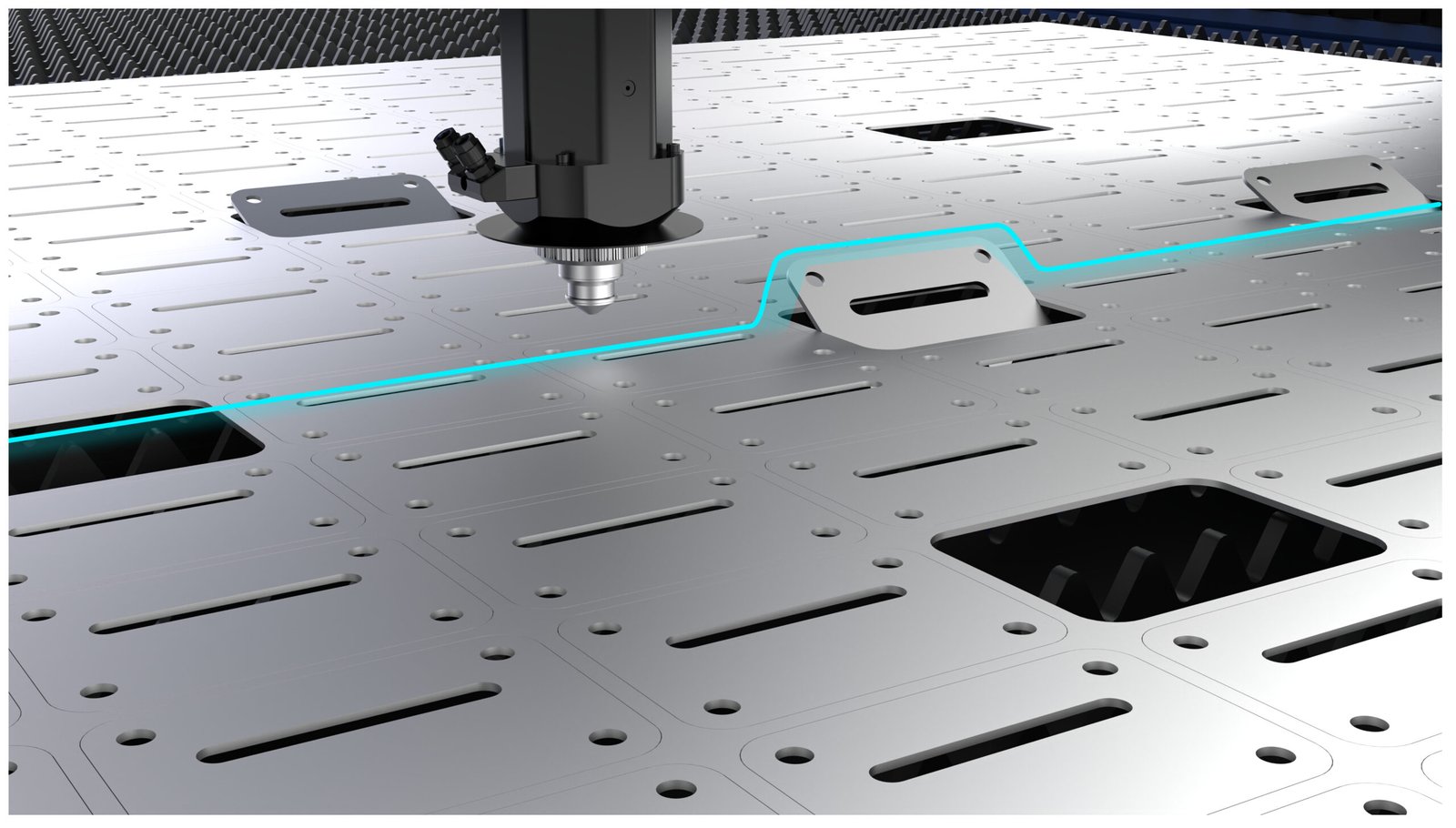

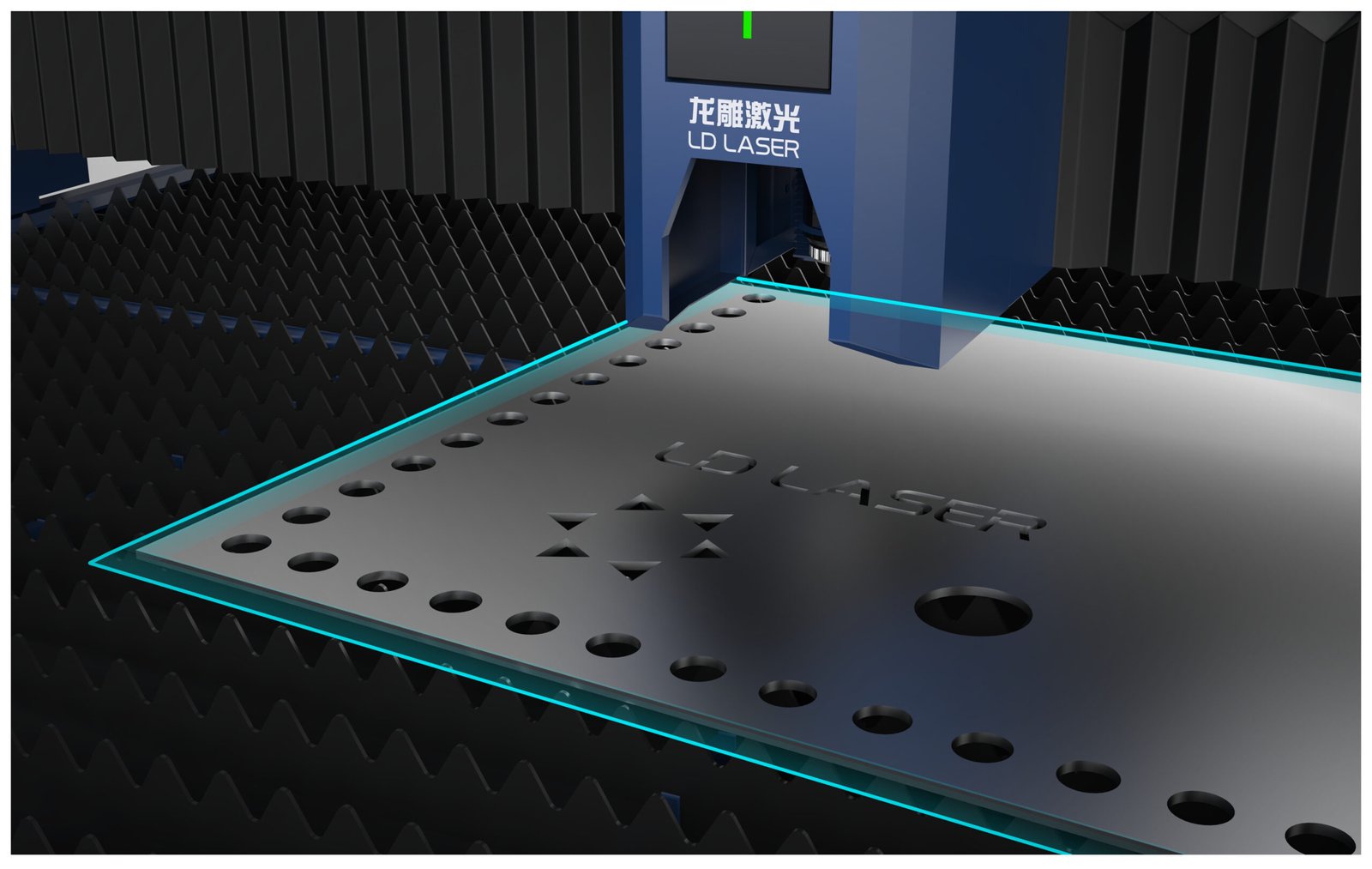

Sense the warping of the plate in advance, automatically avoid obstacles, and reduce the maintenance cost of the laser head.

Ensure that the cutting surface is smooth and without marks, and realize batch cutting to ensure high-efficiency production.

The equipment can intelligently find the edge and adjust the cutting process to suit the angle and position of the sheet material to avoid waste.

Learn more

Both the straight cutting and beveling can be equipped with the Sky Eye system

Intelligent protection and safe production

The beveling system can be optionally equipped with a secondary beveling function

Open single table laser cutting machine

H section steel fiber laser cutting machine

Fully enclosed sheet laser cutting machine

Processing area

3000*1500mm

Positioning accuracy

±0.03mm

Maximum acceleration

1.5G

Processing area

4000*2000mm

Positioning accuracy

±0.03mm

Maximum acceleration

1.5G

Processing area

6000*2000mm

Positioning accuracy

±0.03mm

Maximum acceleration

1.5G

Processing area

6000*2500mm

Positioning accuracy

±0.03mm

Maximum acceleration

1.5G

Processing area

8000*2500mm

Positioning accuracy

±0.03mm

Maximum acceleration

1.5G

Processing area

12000*2500mm

Positioning accuracy

±0.03mm

Maximum acceleration

1.5G

Processing area

12500*2600mm

Positioning accuracy

±0.03mm

Maximum acceleration

1.5G

Processing area

12500*3100mm

Positioning accuracy

±0.03mm

Maximum acceleration

1.5G

You will receive a response within one business day