Ground Rail Fiber Laser Cutting Machine

The gantry features an enclosed structure with sliding maintenance doors for easy equipment access. It incorporates a double-layer dust-proof fabric design on the X-axis: the upper layer minimizes light leakage and light source emission, while the lower layer isolates dust and smoke, protecting the rack guide rails.

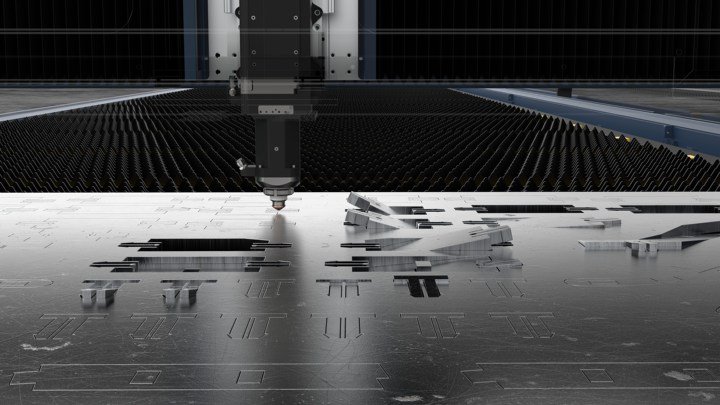

The material platform is designed with an independent modular concept, enabling easy daily replacement and slag cleaning for customers, thereby reducing production costs.

The high-sensitivity safety light screens on both sides of the crossbeam act as loyal guardians, ensuring 360-degree protection for operators during equipment movement.

Rectangular steel is welded to form a classic gantry structure

Annealing to relieve stress and process the shape

Greatly improve the bearing capacity of the beam

The Y-axis rack guide rails incorporate a side-mounted design with sheet metal shielding to prevent collisions and damage during material loading/unloading. By replacing traditional telescoping dust covers with a simplified setup, this design reduces maintenance costs, eliminates compressed storage space for dust curtains, minimizes floor footprint, and maximizes spatial efficiency.

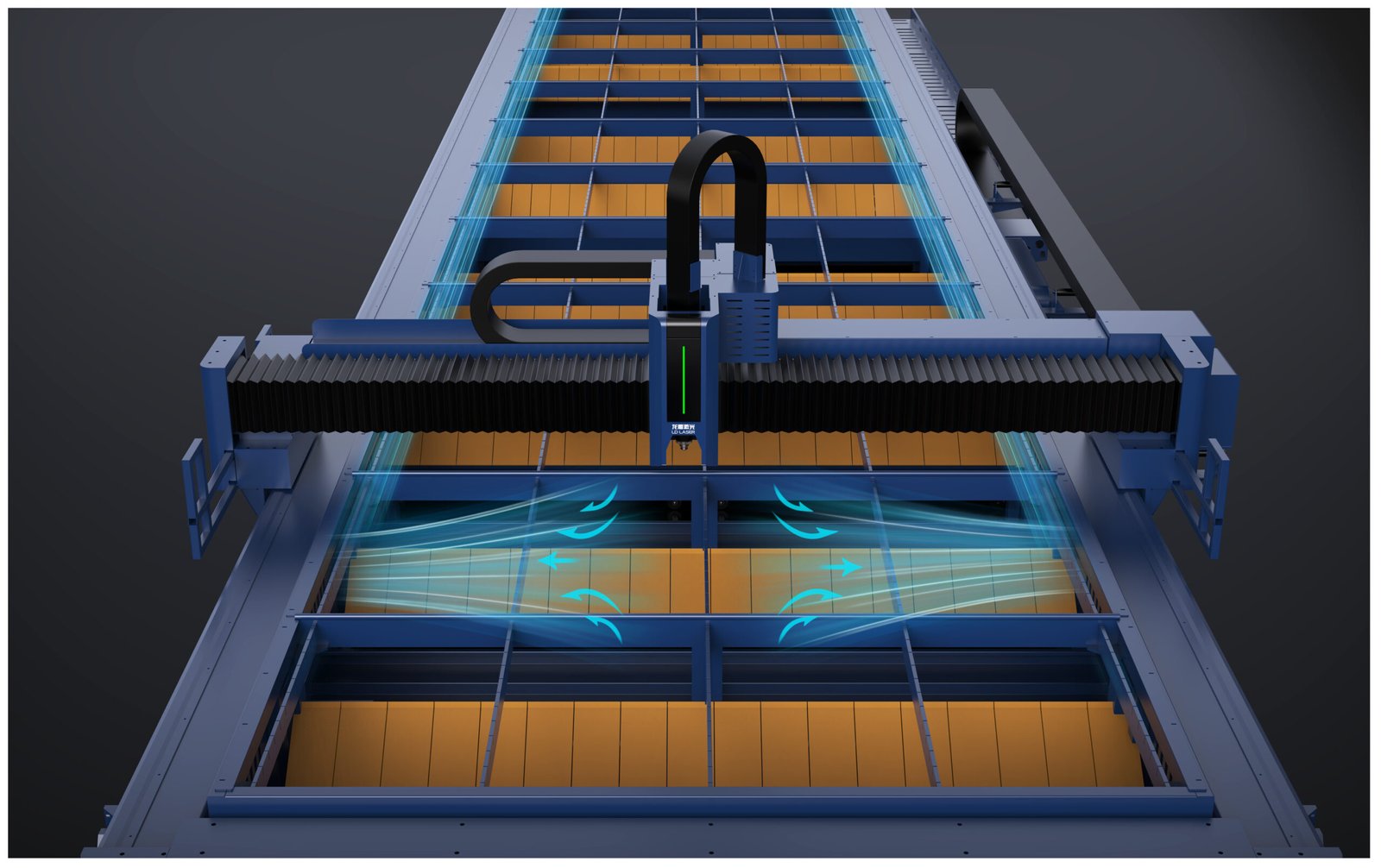

The innovatively upgraded blow-suction exhaust system employs collaborative operation of fans and dust collectors to efficiently purify dust and harmful gases, thereby mitigating risks to equipment and personnel.

The crossbeam base features a precision-engineered arrangement of three slides on each side, ensuring long-term stable and efficient operation while reducing wear on each slide and significantly extending their service life. Additionally, the peripheral sheet metal structure incorporates vibration-damping supports to minimize resonance and vibration, thereby guaranteeing cutting precision

Processing is optimized to be smarter, safer, more convenient, and more efficient by adapting to real cutting conditions.

For large workpieces or batch production requirements, the machine offers customizable machining areas of several meters or even larger, providing scalable solutions for high-volume or oversized part processing.

The machine is factory-equipped with a standard reference tail stock, enabling effortless adjustment of X/Y-axis perpendicularity and precise diagonal cutting accuracy. The integrated crossbeam-tail stock design streamlines transportation, drastically reducing installation workload at the site, thereby accelerating commissioning and operational readiness.

The machine features encrypted footings welded integrally with the base plate, ensuring foundational rigidity comparable to a monolith and exceptional deformation resistance. This design elevates structural strength to new heights.

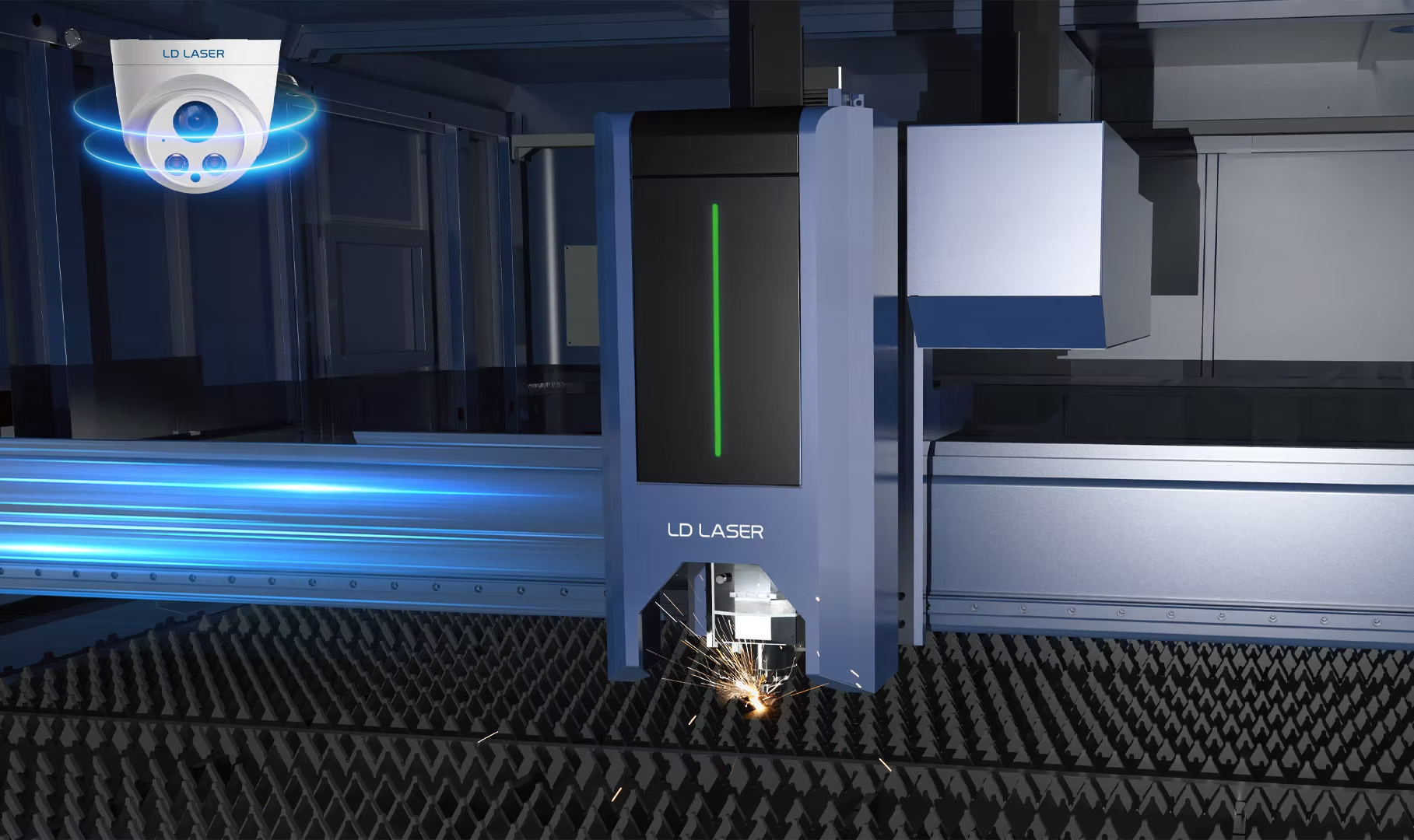

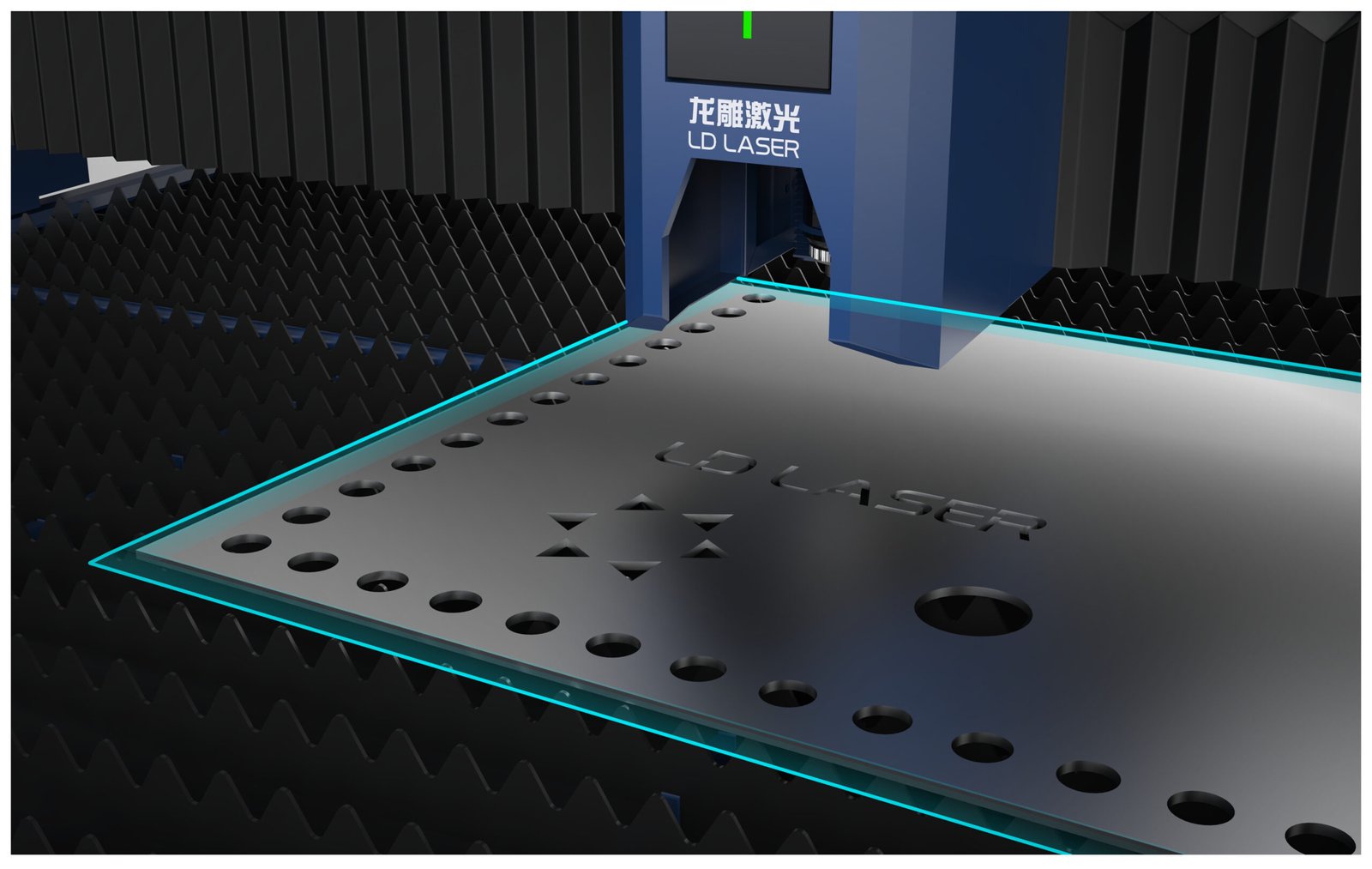

The cutting quality can be judged through the equipment sensors, and the parameters can be adjusted in real time to improve the cutting efficiency and stability.

Based on the actual cutting conditions of the equipment, we can achieve smarter, safer, more convenient and more efficient processing

The ultra-large diameter air duct design is adopted, with independent control and partitioned dust removal to improve the smoke exhaust and heat removal effects

Equipped with ultra-high-definition large-size industrial control screen, equipped with intelligent control system, rich functions, intelligent adjustment, safe production

Through intelligent system monitoring, real-time adjustment of air pressure detection to ensure stable cutting

The equipment’s all-round monitoring system records the entire process of workpiece cutting while ensuring worker safety

Intelligent bus control system

Fast response, high precision, fast data transmission

Achieve highly intelligent and flexible cutting

The equipment is equipped with a new generation (HypCut) smart operating system

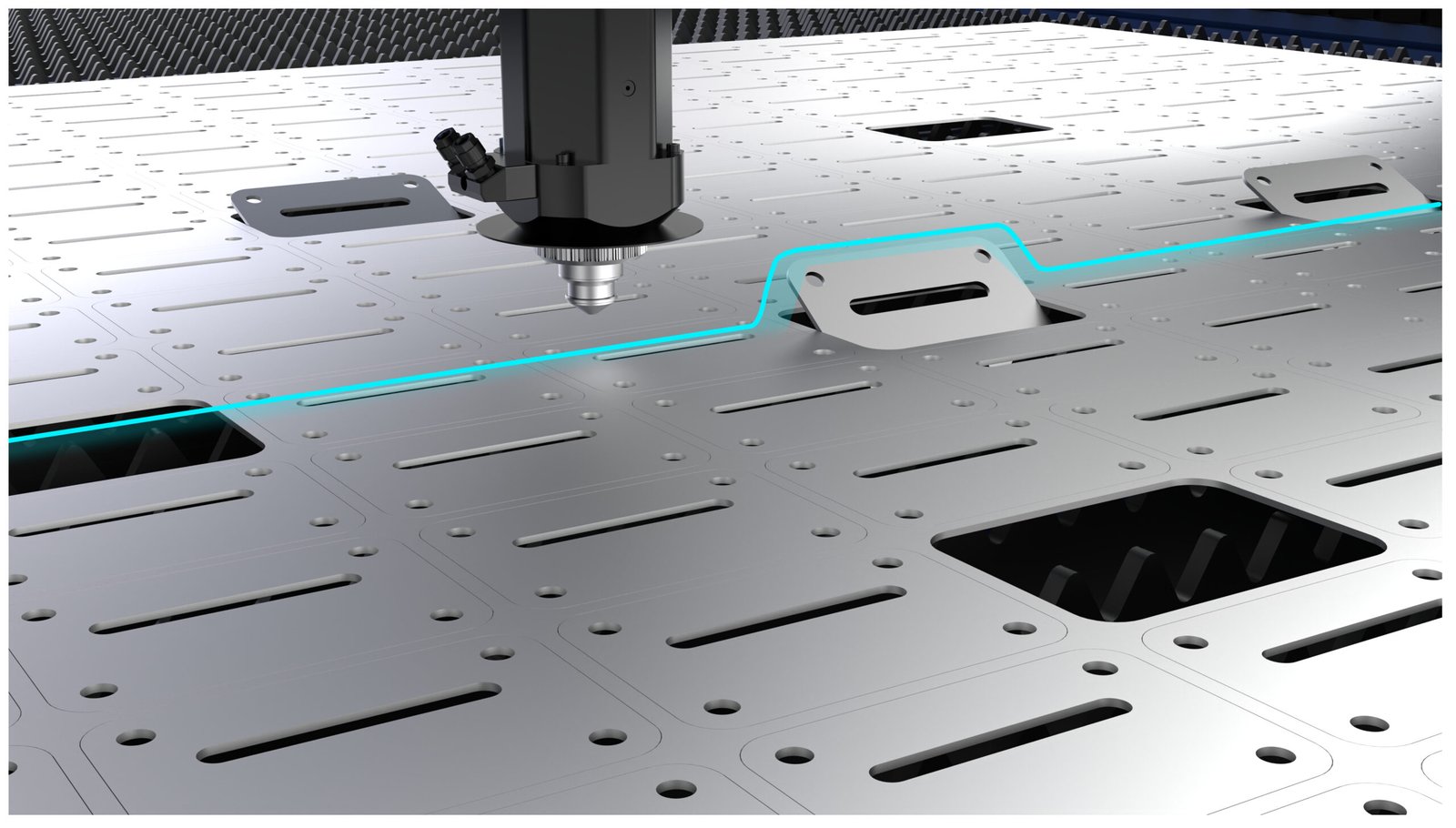

Sense the warping of the plate in advance, automatically avoid obstacles, and reduce the maintenance cost of the laser head.

Ensure that the cutting surface is smooth and without marks, and realize batch cutting to ensure high-efficiency production.

The equipment can intelligently find the edge and adjust the cutting process to suit the angle and position of the sheet material to avoid waste.

Learn more

Ultra High Power Sheet Metal Laser Cutting Machine

Single platform laser cutting machine

Fully enclosed sheet laser cutting machine

Processing area

14000*3500mm

Positioning accuracy

±0.03mm

Processing area

16000*4500mm

Positioning accuracy

±0.03mm

Processing area

25000*3100mm

Positioning accuracy

±0.03mm

Processing area

25000*3500mm

Positioning accuracy

±0.03mm

Processing area

25000*4000mm

Positioning accuracy

±0.03mm

Processing area

25000*4500mm

Positioning accuracy

±0.03mm

You will receive a response within one business day