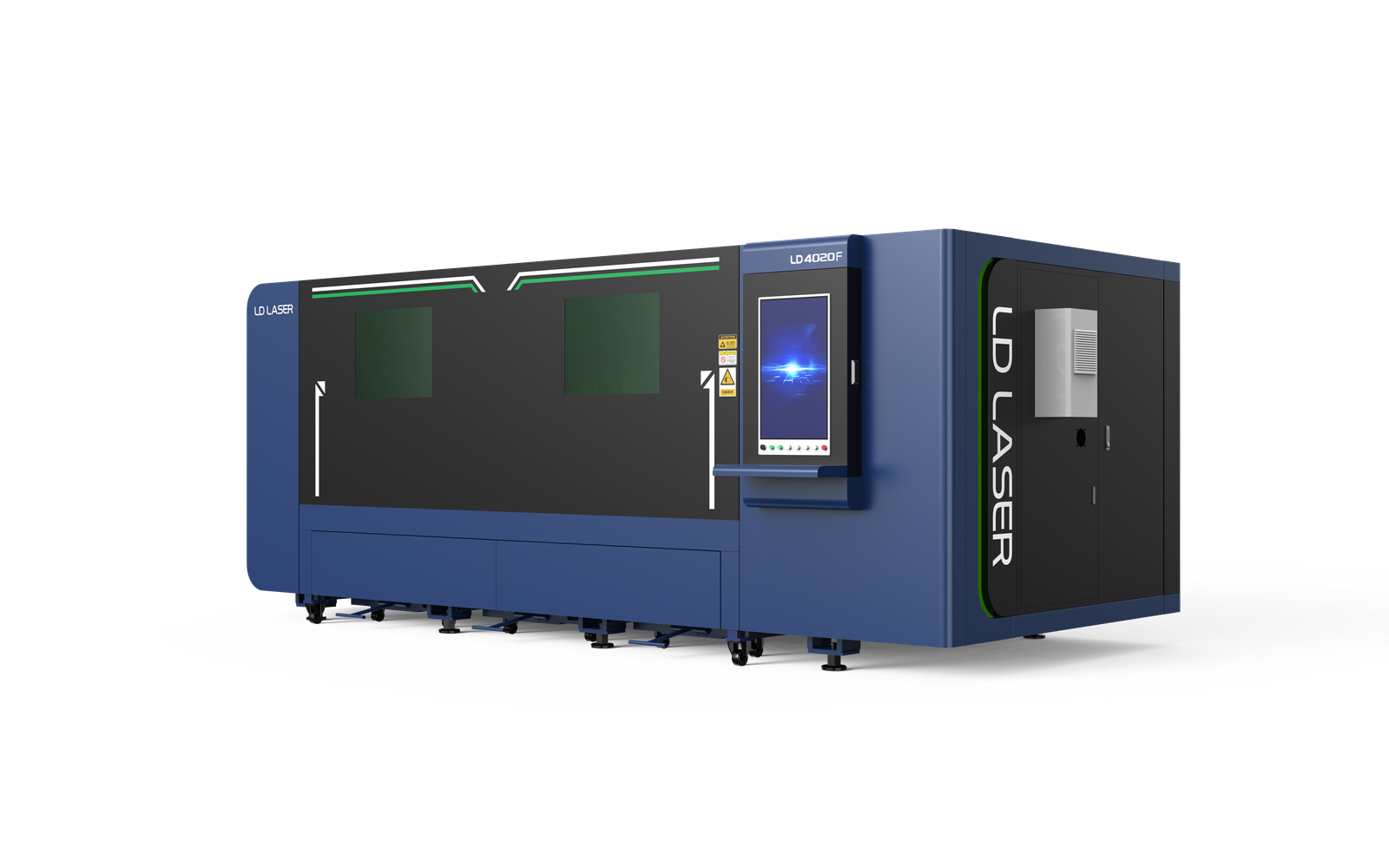

Single Table Panel Fiber Laser Cutting Machine

Monolithic Bed Design with dovetail joint structure and fully welded tube-plate integration, stress-relieved through high-temperature annealing to prevent deformation and ensure extended service life.

Rectangular steel is welded to form a classic gantry structure

Annealing to relieve stress and process the shape

Greatly improve the bearing capacity of the beam

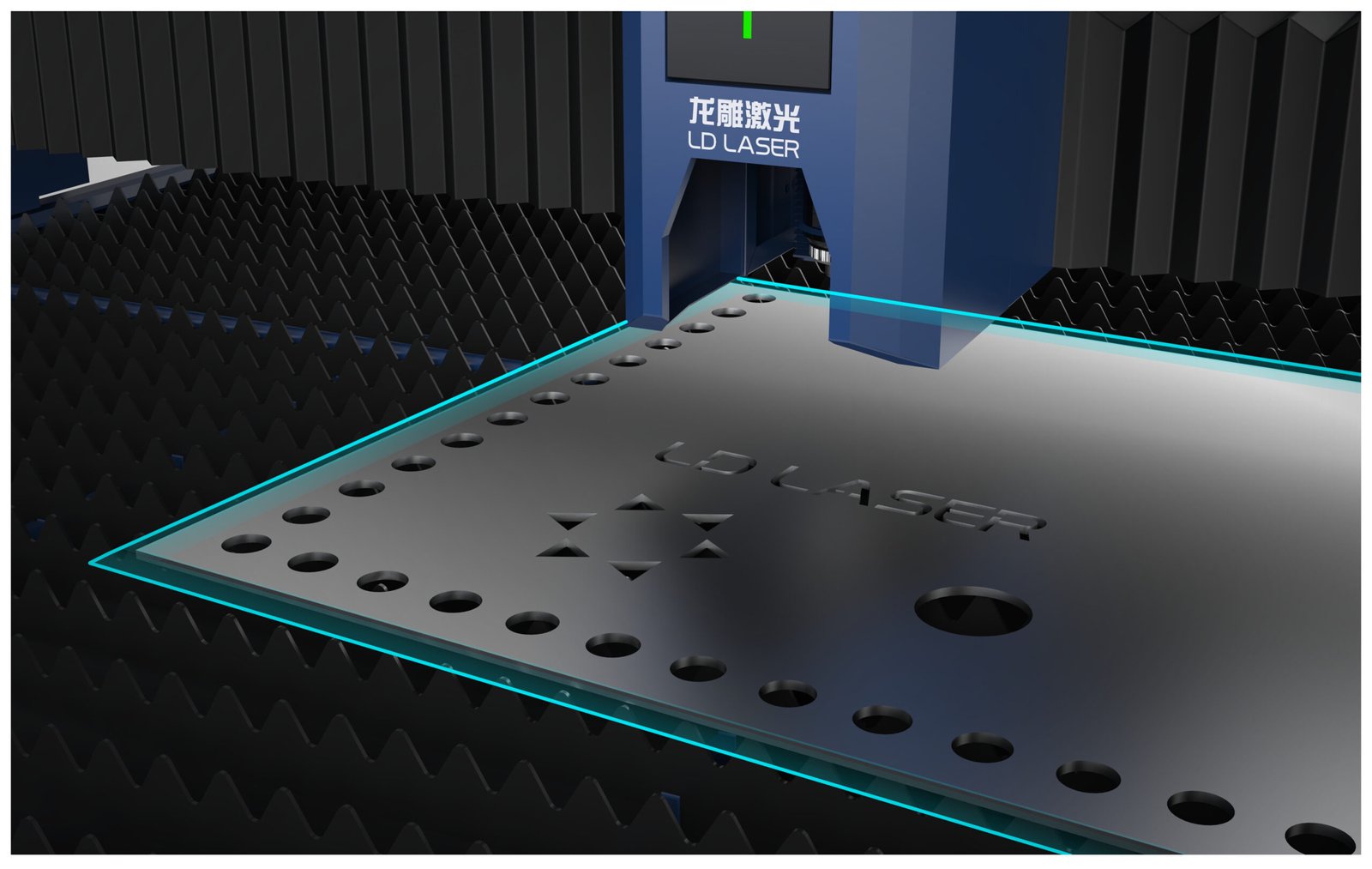

The machine incorporates next-generation composite refractory bricks, delivering unmatched slag resistance, fireproofing, and thermal stability—reducing maintenance labor by 50%while extending service life 3X versus traditional materials.

Processing is optimized to be smarter, safer, more convenient, and more efficient by adapting to real cutting conditions.

The integrated power cabinet merges seamlessly with the machine body, reducing footprint by 40% compared to external cabinet designs.

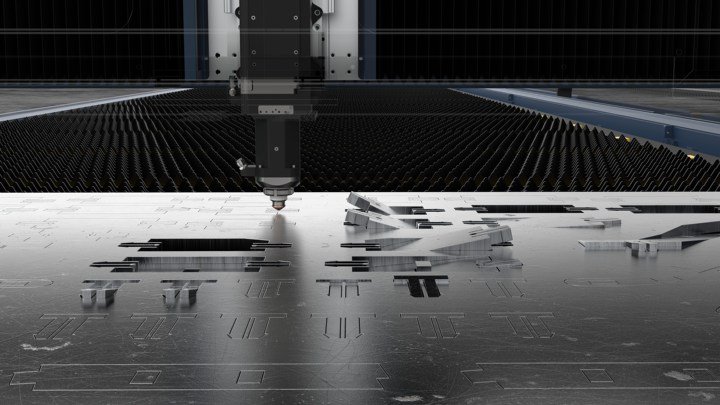

Single-platform open structure allows material handling from three directions, optimizing workflow efficiency.

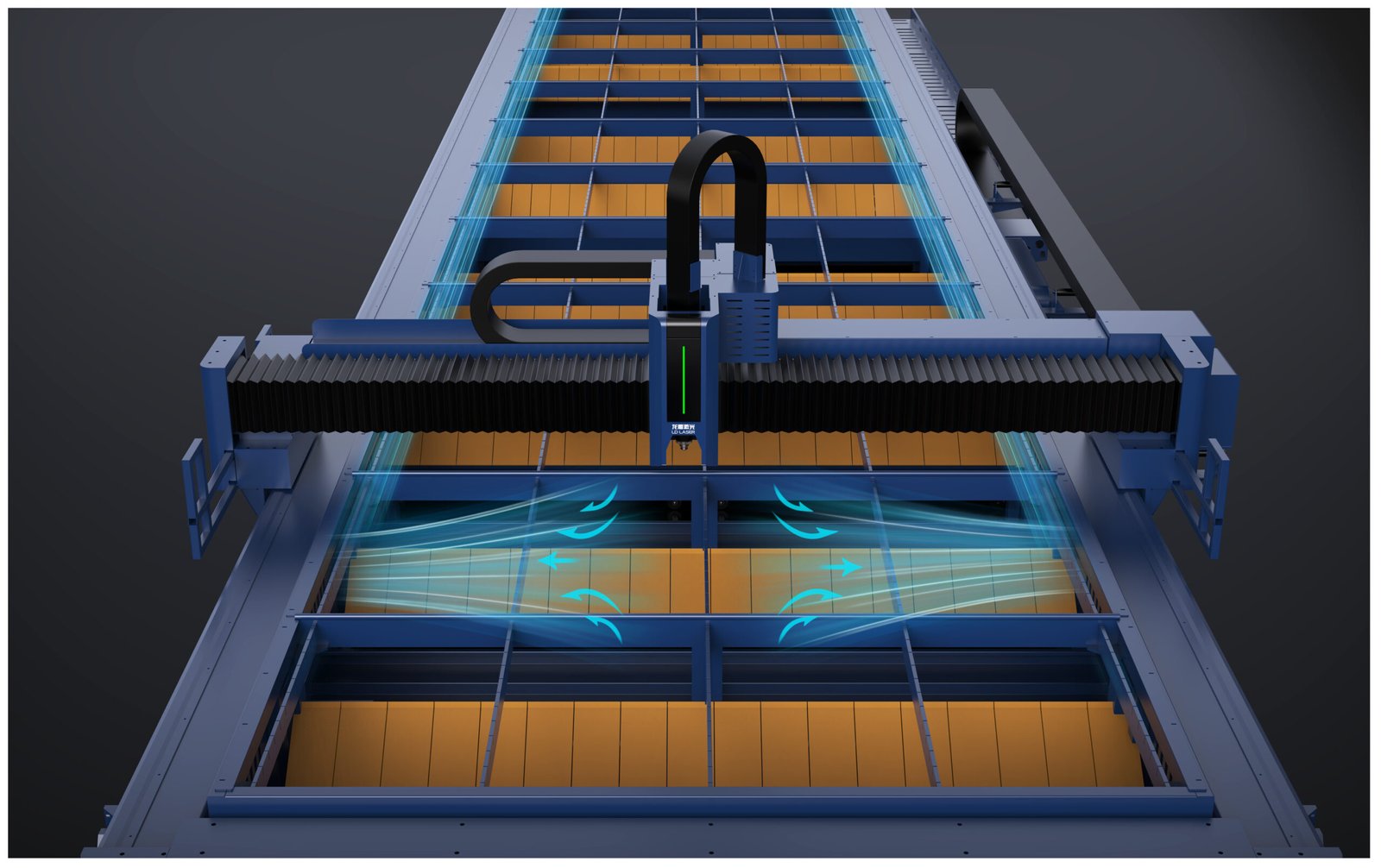

The partitioned dust removal system delivers targeted suction for more thorough debris collection compared to conventional single-zone designs.

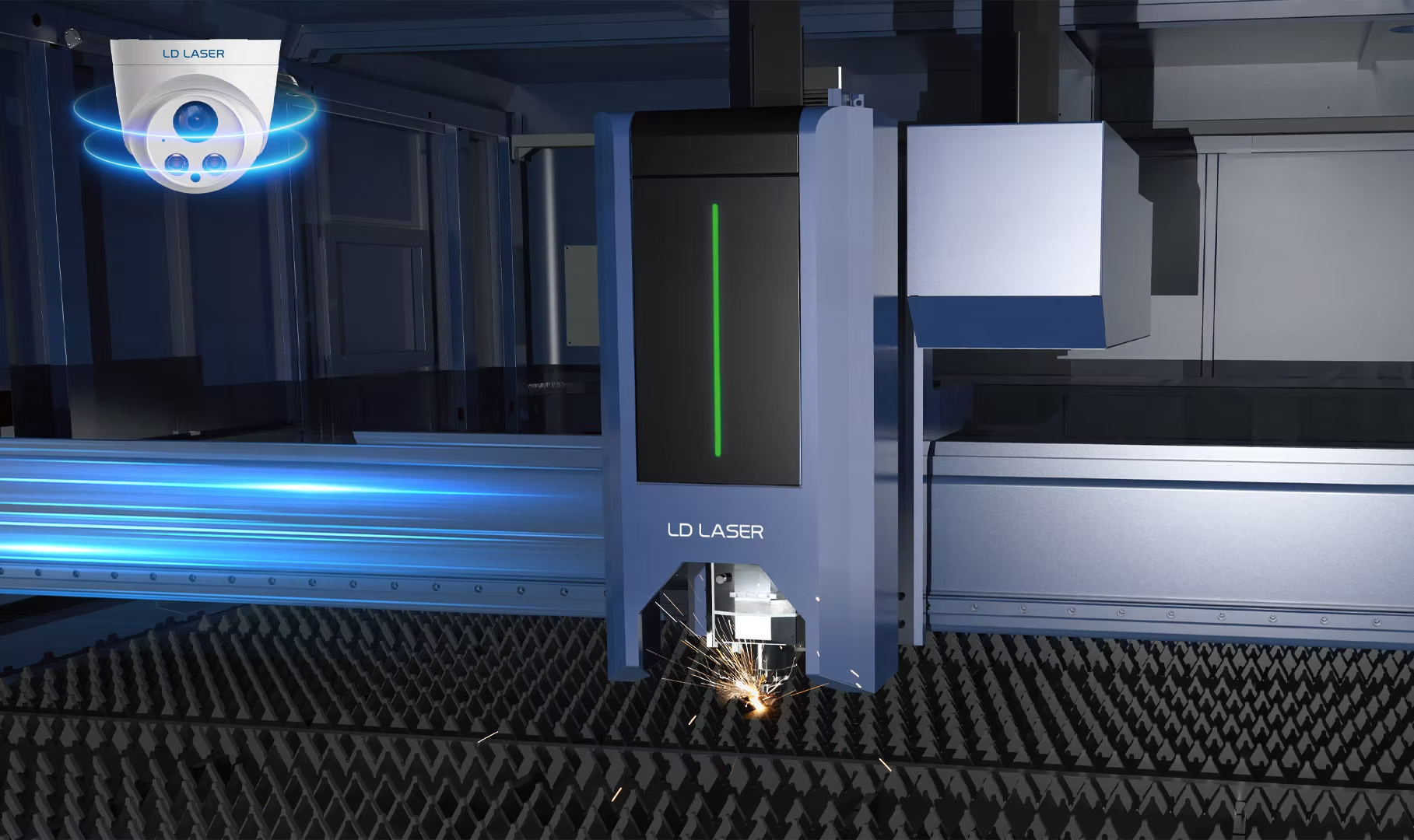

The cutting quality can be judged through the equipment sensors, and the parameters can be adjusted in real time to improve the cutting efficiency and stability.

Based on the actual cutting conditions of the equipment, we can achieve smarter, safer, more convenient and more efficient processing

The ultra-large diameter air duct design is adopted, with independent control and partitioned dust removal to improve the smoke exhaust and heat removal effects

Equipped with ultra-high-definition large-size industrial control screen, equipped with intelligent control system, rich functions, intelligent adjustment, safe production

Through intelligent system monitoring, real-time adjustment of air pressure detection to ensure stable cutting

The equipment’s all-round monitoring system records the entire process of workpiece cutting while ensuring worker safety

The equipment is equipped with a new generation (HypCut) smart operating system

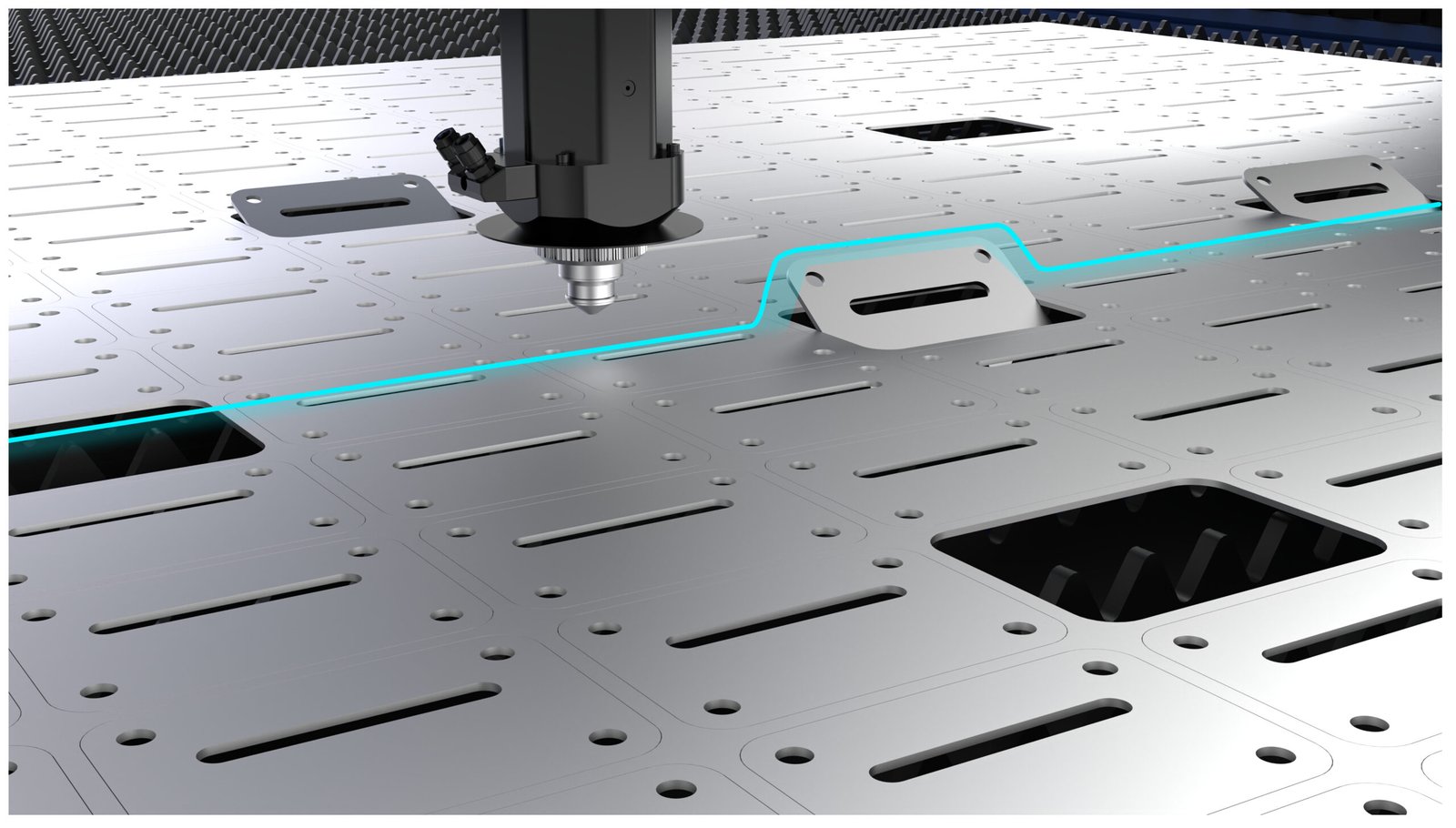

Sense the warping of the plate in advance, automatically avoid obstacles, and reduce the maintenance cost of the laser head.

Ensure that the cutting surface is smooth and without marks, and realize batch cutting to ensure high-efficiency production.

The equipment can intelligently find the edge and adjust the cutting process to suit the angle and position of the sheet material to avoid waste.

Learn more

Efficiency improvement30%

Intelligent protection and safe production

Intelligent bevel cutting head can achieve ±45° bevel cutting, forming multiple bevels at one time, doubling cutting efficiency.

Ultra high power laser cutting machine

Ground rail fiber laser cutting machine

Fully enclosed sheet laser cutting machine

Processing area

3000*1500mm

Positioning accuracy

±0.03mm

Processing area

4000*1500mm

Positioning accuracy

±0.03mm

Processing area

4000*2000mm

Positioning accuracy

±0.03mm

Processing area

6000*1500mm

Positioning accuracy

±0.03mm

Processing area

6000*2000mm

Positioning accuracy

±0.03mm

Processing area

6000*2500mm

Positioning accuracy

±0.03mm

Processing area

8000*2000mm

Positioning accuracy

±0.03mm

Processing area

8000*2500mm

Positioning accuracy

±0.03mm

Processing area

13000*2500mm

Positioning accuracy

±0.03mm

Processing area

14000*3100mm

Positioning accuracy

±0.03mm

Processing area

25000*3100mm

Positioning accuracy

±0.03mm

You will receive a response within one business day