Science and Education

We offer standardized laser application solutions for the production of a wide range of office furniture and scientific research instruments. This includes analytical instruments, measuring devices, laboratory equipment, and various other tools.

Industry pain points

Inflexible processing

Traditional equipment is designed for a single function.

Achieving flexible processing with such equipment is challenging.

Moreover, ensuring personal safety is often impossible.

Poor processing accuracy

Limitations in the production process can lead to various challenges.

These challenges often result in inconsistent quality, which can affect overall satisfaction.

Additionally, issues with accuracy can lead to higher waste levels, impacting efficiency and profitability.

Low production efficiency

The manufacturing process is intricate and multifaceted.

It involves various stages of additional processing and polishing to achieve the desired finish.

However, one significant drawback is the high labor costs associated with these operations.

Specific Applications

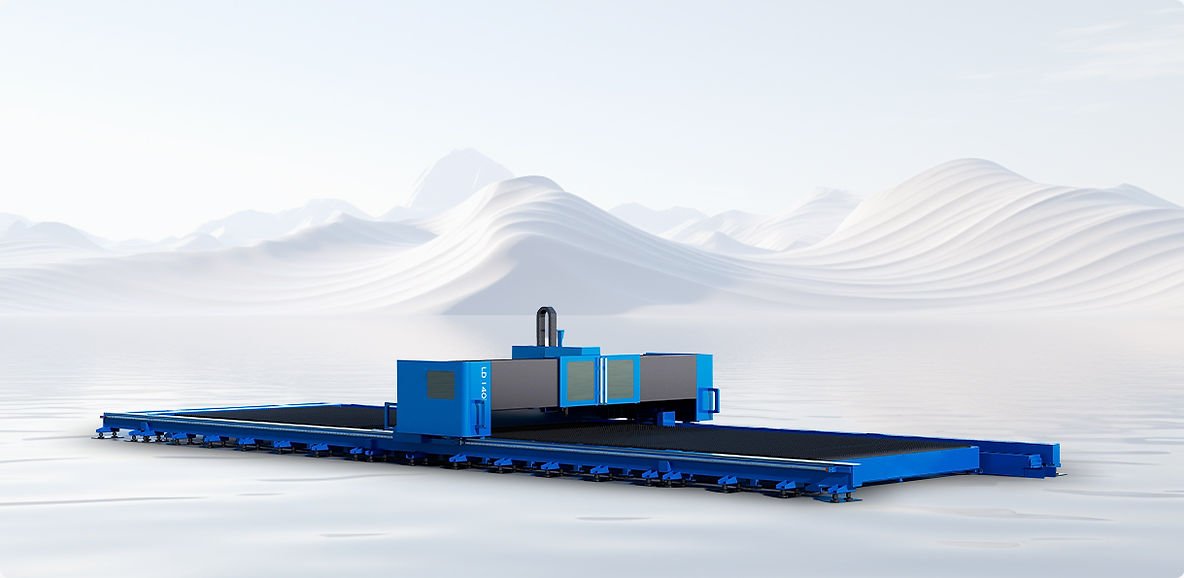

The scientific, educational, and office sectors have various processing needs, which include a wide range of specifications, high precision requirements, top-notch processing quality, and complex workflows. LD LASER processing offers a flexible and efficient solution, allowing for customizable and adaptable processing of different plate and pipe thicknesses in large batches.

The end products achieved through this processing method are smooth and burr-free, eliminating the need for any secondary processing. This significantly enhances both quality and efficiency, making it a valuable option for many industries.

This includes the sheet metal fabrication of various analytical instruments, measuring devices, electronic measuring tools, medical diagnostic equipment, physical properties testing apparatus, atmospheric detection instruments, and other scientific devices.

Our focus includes the processing of metal parts and components for a variety of devices. This encompasses computers, copiers, fax machines, printers, projectors, scanners, cameras, routers, and more.

We ensure that each component meets the necessary specifications and standards for optimal performance in these essential technologies.

We specialize in the processing of sheet metal parts and components for a variety of products including wardrobes, lockers, multi-drawer cabinets, miscellaneous cabinets, safes, office desks, office chairs, and more.

Our expertise ensures that each piece is crafted with precision to meet your specific needs, focusing on quality and durability across all applications.

Whether you require components for home furniture or office solutions, our attention to detail guarantees top-notch results every time.

Learn more about customer cases

Excellent product and service experience, shaping global customer reputation

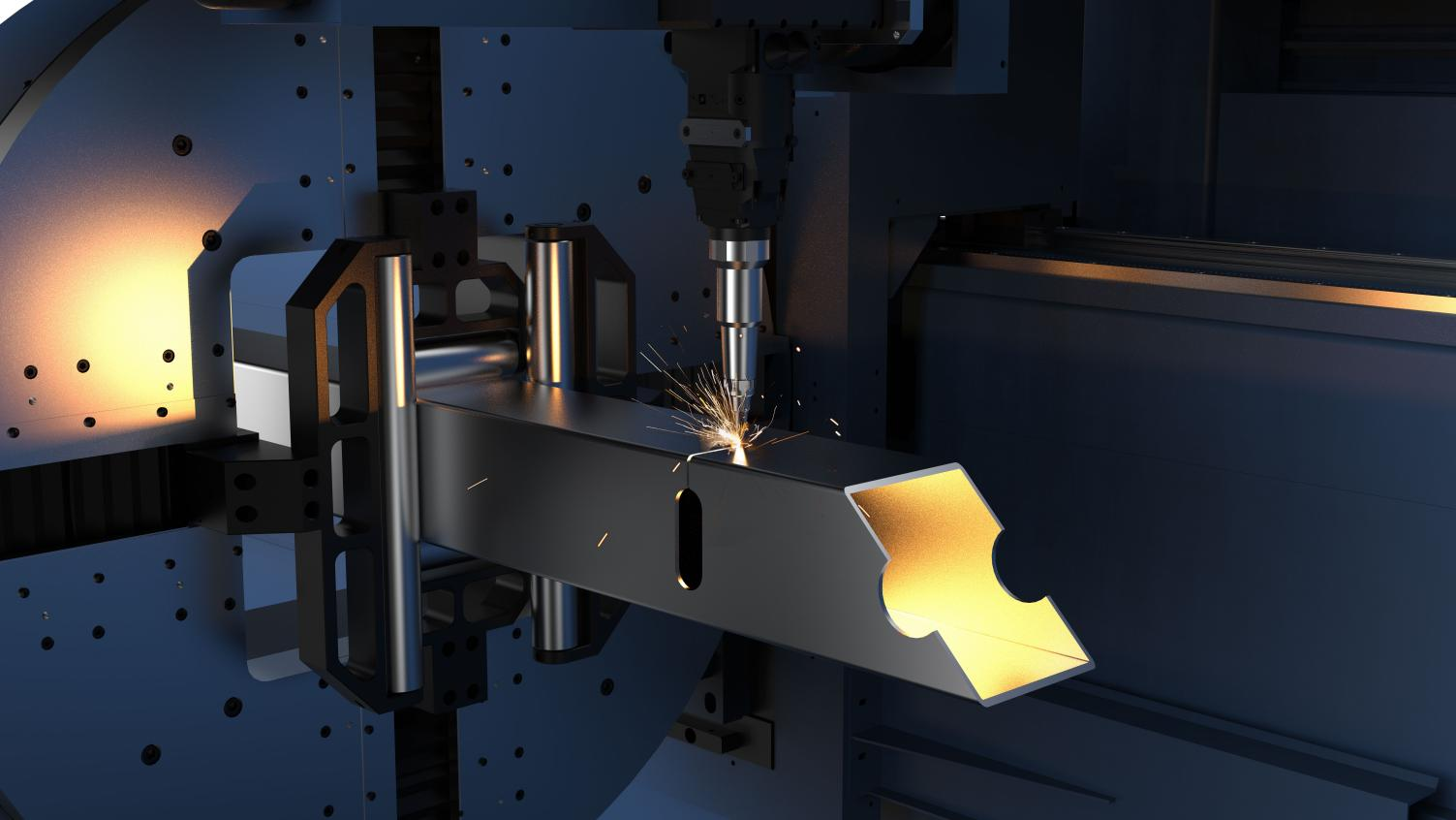

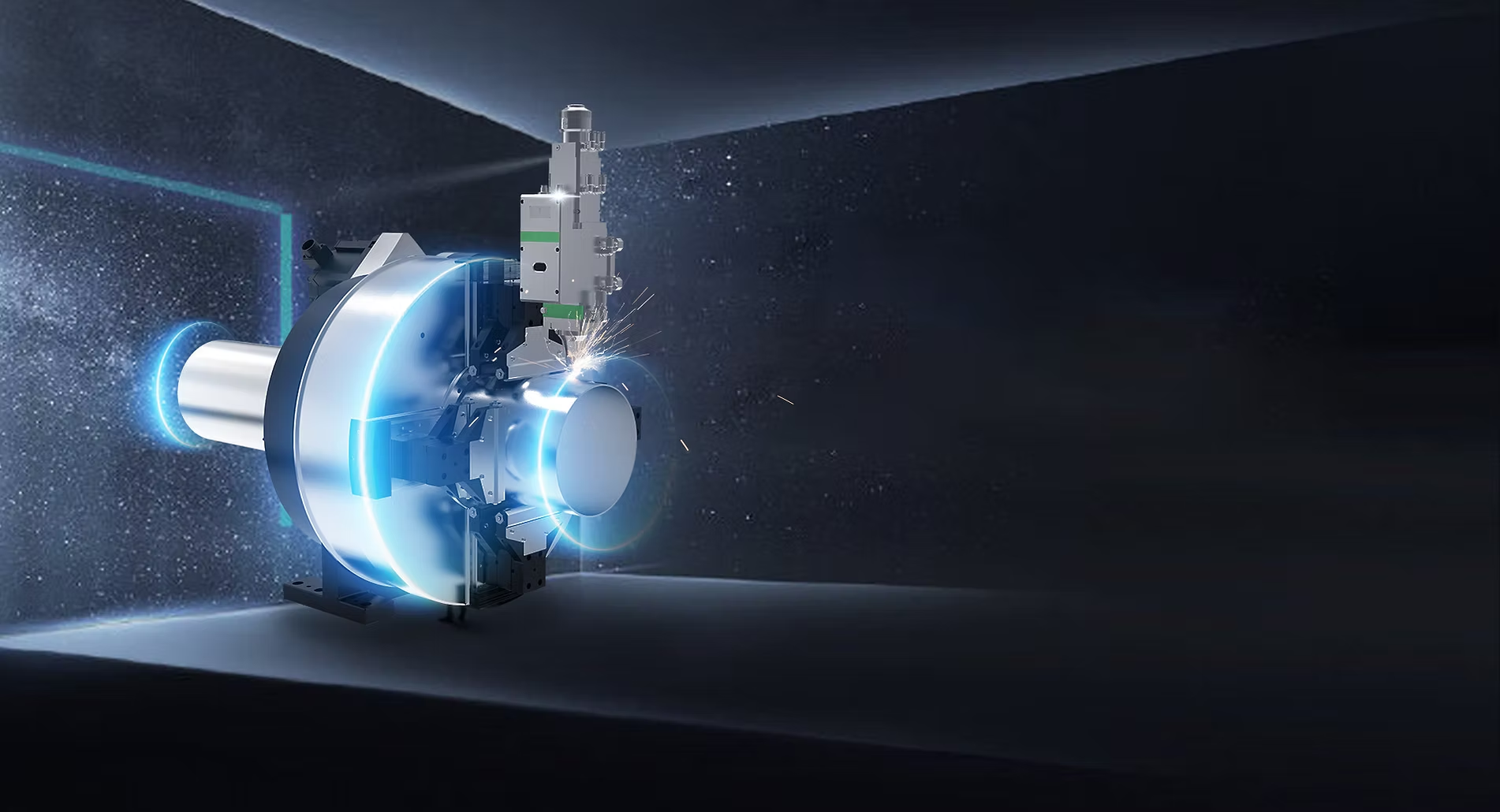

Tubular Revolution Unlocking New Possibilities With Tube Laser Cutting

Glimpse into the future of manufacturing as tube laser cutting shatters traditional limits and unlocks design possibilities never imagined before.

Tube Laser Cutting A Streamlined Construction Process

Precision tube laser cutting revolutionizes construction with automated accuracy, but what makes it truly indispensable for modern manufacturing?

How to Open up New Design Possibilities With Tube Laser Cutting Machines

Keep your metal projects limitless by mastering tube laser cutting machines and unlocking revolutionary design capabilities you never thought possible.

Learn more about LD LASER products

There is always a product suitable for you