Elevator

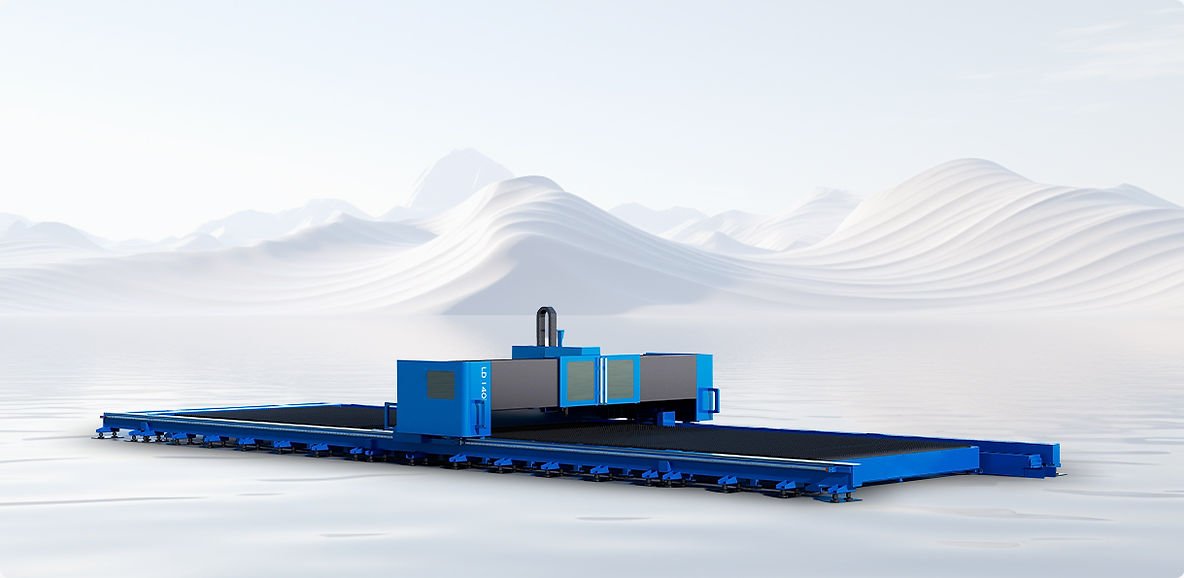

Offer standardized laser application solutions for processing related accessories within the elevator manufacturing industry.

Industry pain points

Poor processing accuracy

Limitations in the production process can lead to significant challenges.

One of the main issues is the uneven quality of the products being made.

Additionally, there is often poor accuracy, which can result in high levels of waste.

Low production efficiency

The manufacturing process is intricate and involves multiple stages that require careful execution.

Additionally, secondary processing and polishing are crucial steps that contribute to the final quality of the product.

However, the high labor costs associated with these processes can significantly impact overall production expenses.

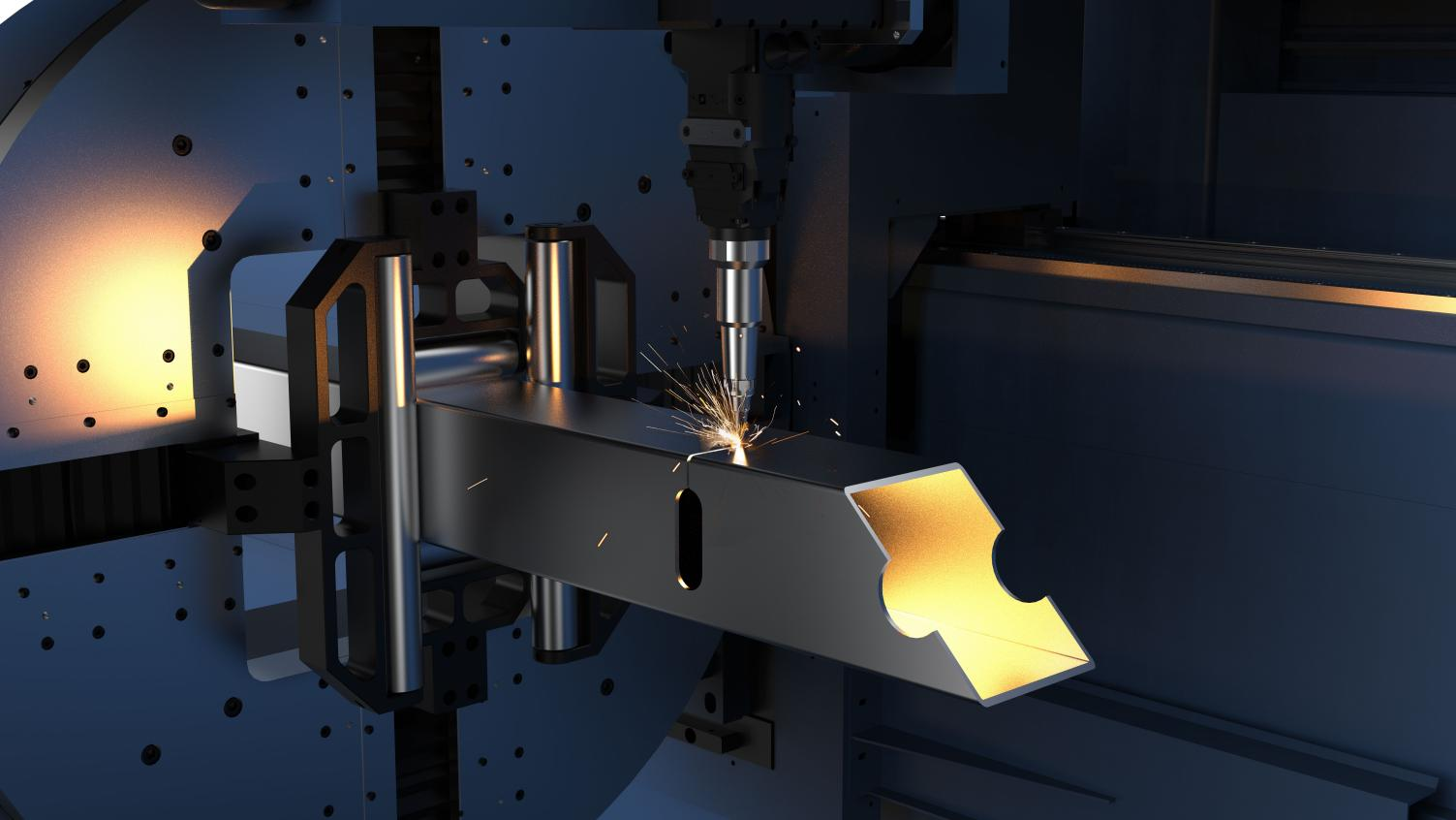

Severe cutting deformation

High tangential stress occurs during certain machining processes, leading to significant challenges in the material being worked on.

This results in large plastic deformation, where the material undergoes permanent changes in shape or size due to the intense forces applied to it.

As a consequence, a considerable cutting force is required to achieve the desired outcomes, making the machining operations more demanding and complex.

Specific Applications

The elevator industry has stringent requirements for high-quality stainless steel materials. These materials are known for their strength, but cutting them can generate significant tangential stress, plastic deformation, and cutting force. The LD LASER cutting machine offers numerous advantages, including excellent beam quality, high precision, a narrow kerf, and efficient material use. It also produces a smooth cutting surface and ensures safe operation.

After processing with this cutting machine, the finished products come out smooth and free from burrs, eliminating the need for secondary processing. This efficiency greatly enhances both the quality of the final product and the overall productivity of the manufacturing process.

The focus is primarily on the production of various components for elevators, including sheet metal fishplates, door panels, elevator doors, car bodies, structural parts, and several other related components.

The main focus is on the processing of wall panels and the structural support components located on both sides of the escalator.

Learn more about customer cases

Excellent product and service experience, shaping global customer reputation

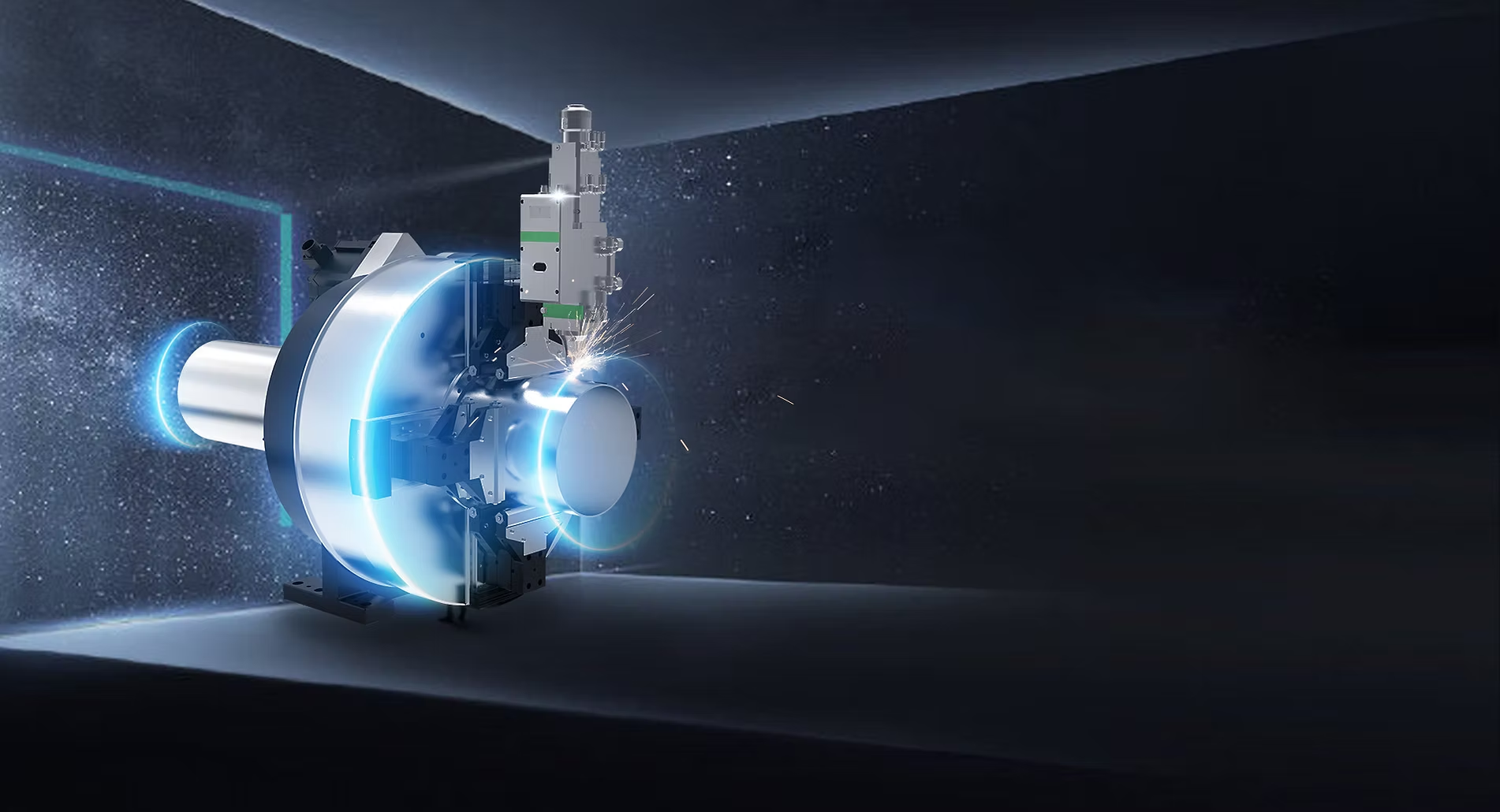

Tubular Revolution Unlocking New Possibilities With Tube Laser Cutting

Glimpse into the future of manufacturing as tube laser cutting shatters traditional limits and unlocks design possibilities never imagined before.

Tube Laser Cutting A Streamlined Construction Process

Precision tube laser cutting revolutionizes construction with automated accuracy, but what makes it truly indispensable for modern manufacturing?

How to Open up New Design Possibilities With Tube Laser Cutting Machines

Keep your metal projects limitless by mastering tube laser cutting machines and unlocking revolutionary design capabilities you never thought possible.

Learn more about LD LASER products

There is always a product suitable for you