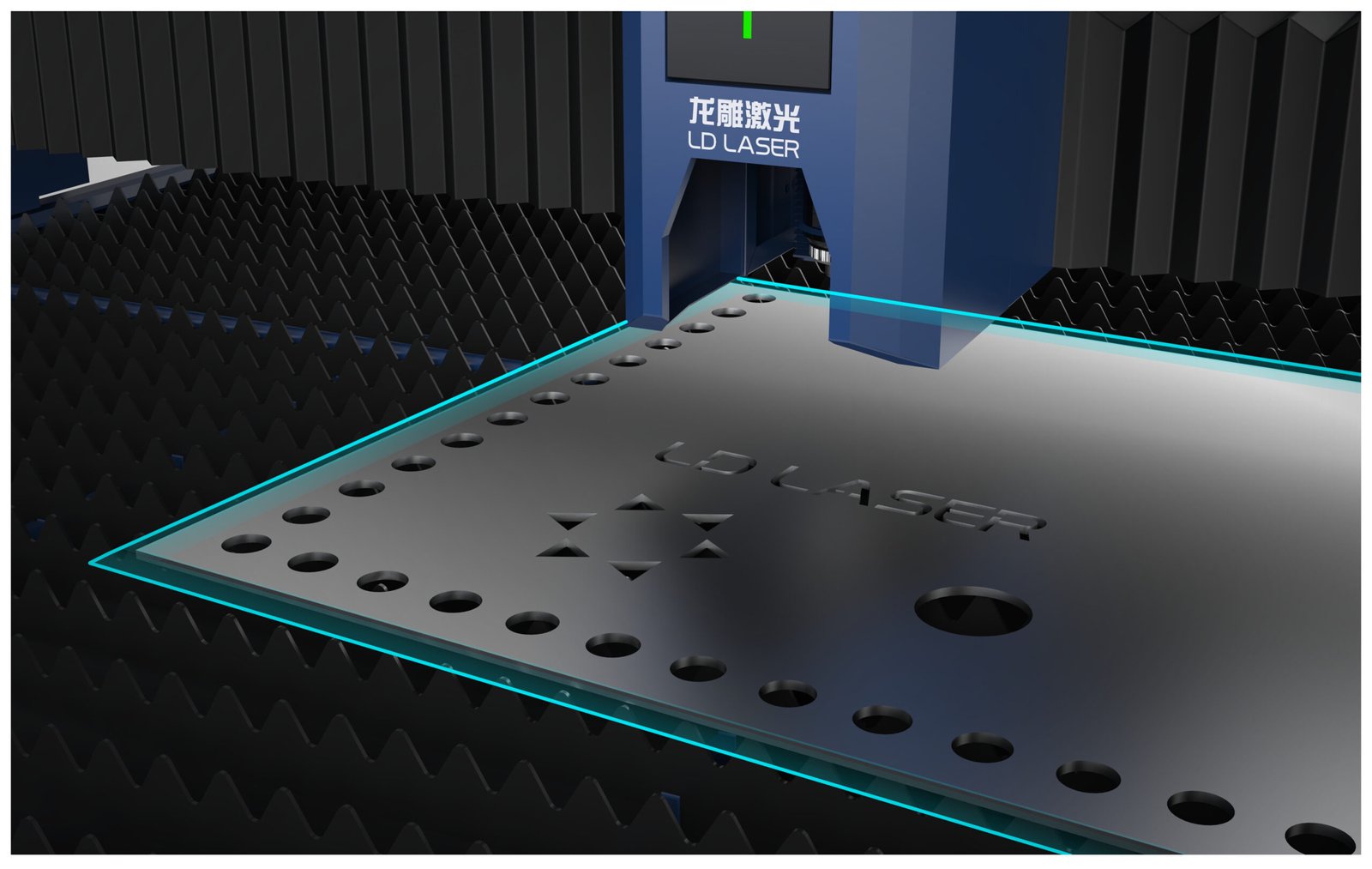

Sheet And Tube Multi Laser Cutting Machine

Monolithic bed structure utilizes mortise-and-tenon joints with integrated tube-plate welding. High-temperature stress-relief annealing ensures deformation-free performance and extended service life.

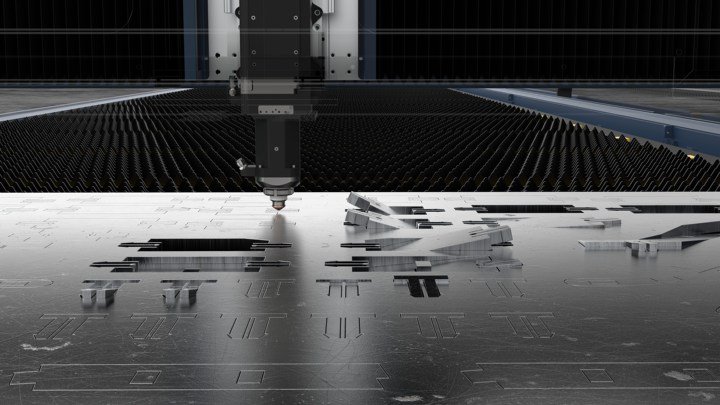

Unified cutting platform processes both flat sheets and tubular profiles across various metallic materials.

Dedicated tubing supports prevent sagging deformation, improving cutting accuracy while prolonging chuck service life.

Open-frame structure enables three-directional material loading/unloading. Achieves equivalent cutting area with 40% smaller footprint than conventional designs.

Processing is optimized to be smarter, safer, more convenient, and more efficient by adapting to real cutting conditions.

The system supports bevel cutting with dual-chuck clamping, enabling precise processing of various irregular tubular profiles.

Standard auto-focus cutting head eliminates manual adjustment:

The precision chuck features a monolithic integrated design with superior dust-proof sealing to prevent cutting debris ingress, ensuring long-term cutting accuracy and equipment longevity.

Key Features:

Built-in cylinder for compact installation, with side-mounted pneumatic ports enabling quick clamping/release

Full-range tube compatibility for enhanced productivity

4-jaw guided rail mechanism maintains linear motion stability

0.05mm repeat positioning accuracy

200 RPM max speed (Note: Rapid traverse speed should be reduced proportionally with increased tube weight)

Movable front chuck optimizes end-cut precision and minimizes material waste during tail-end processing

The cutting quality can be judged through the equipment sensors, and the parameters can be adjusted in real time to improve the cutting efficiency and stability.

Based on the actual cutting conditions of the equipment, we can achieve smarter, safer, more convenient and more efficient processing

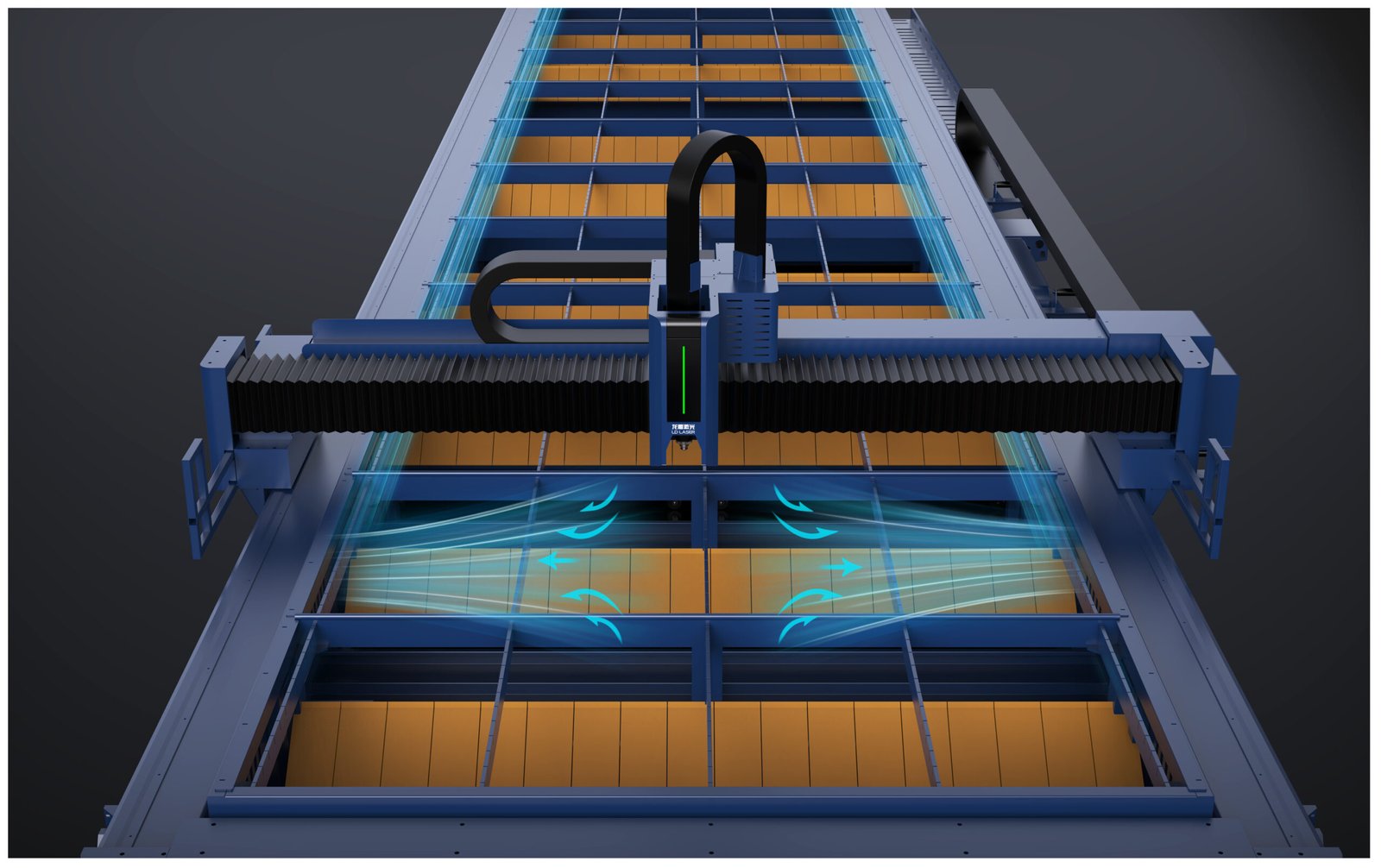

The ultra-large diameter air duct design is adopted, with independent control and partitioned dust removal to improve the smoke exhaust and heat removal effects

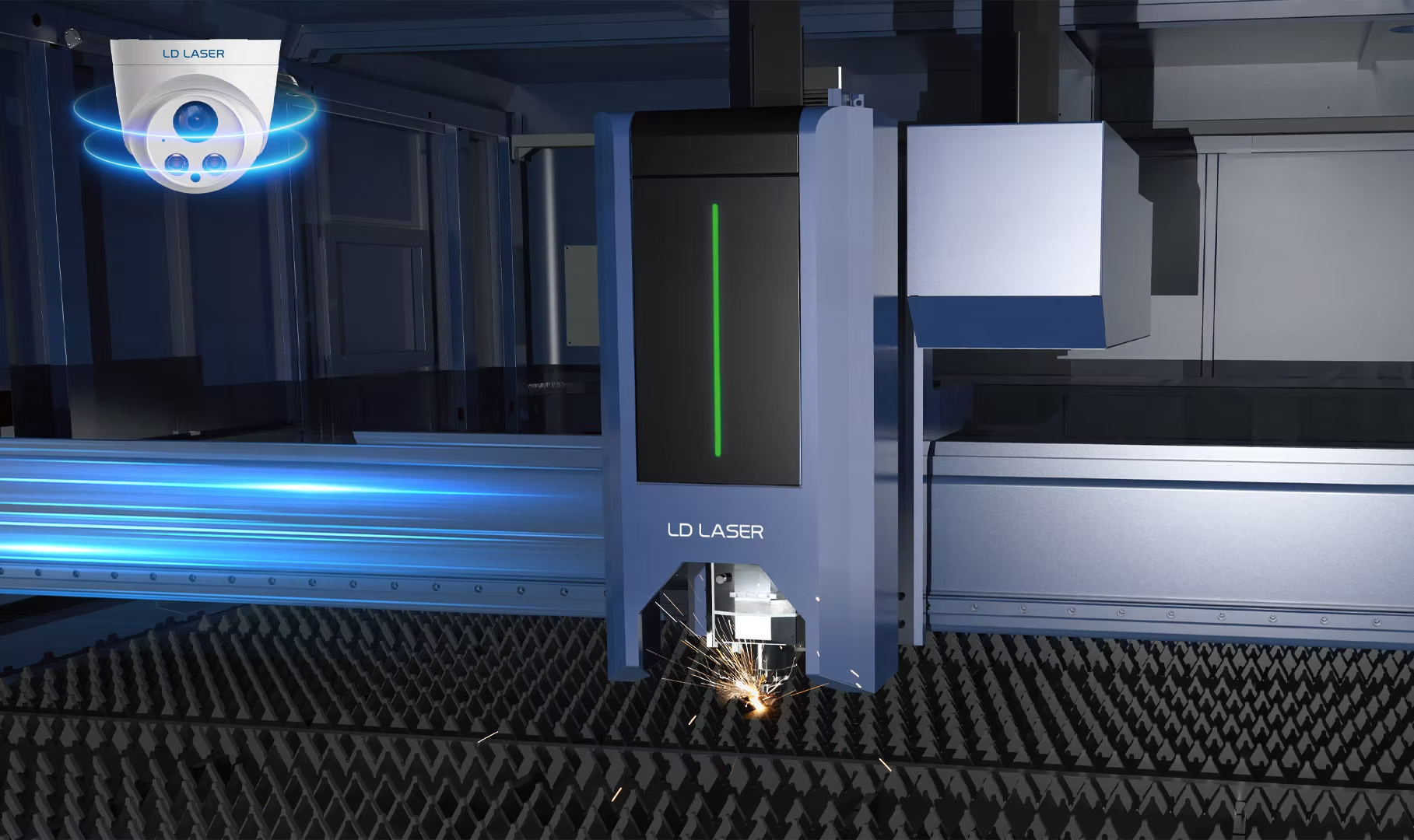

Equipped with ultra-high-definition large-size industrial control screen, equipped with intelligent control system, rich functions, intelligent adjustment, safe production

Through intelligent system monitoring, real-time adjustment of air pressure detection to ensure stable cutting

The equipment’s all-round monitoring system records the entire process of workpiece cutting while ensuring worker safety

The equipment is equipped with a new generation (HypCut) smart operating system

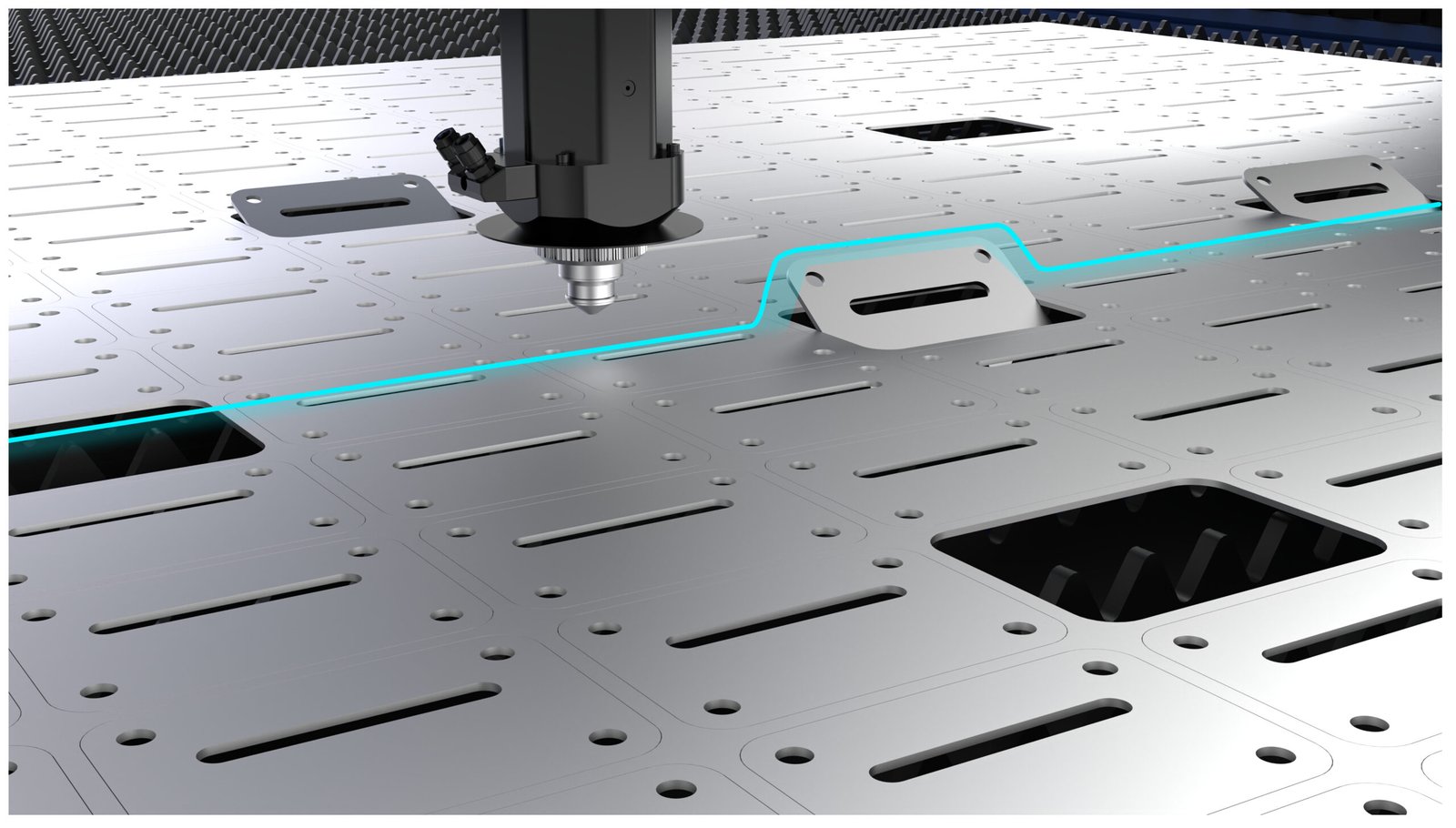

Sense the warping of the plate in advance, automatically avoid obstacles, and reduce the maintenance cost of the laser head.

Ensure that the cutting surface is smooth and without marks, and realize batch cutting to ensure high-efficiency production.

The equipment can intelligently find the edge and adjust the cutting process to suit the angle and position of the sheet material to avoid waste.

Learn more

Efficiency improvement30%

Intelligent protection and safe production

Intelligent bevel cutting head can achieve ±45° bevel cutting, forming multiple bevels at one time, doubling cutting efficiency.

Sheet And Tube Multi Laser Cutting Machine

Processing area

3000*1500mm

Pipe processing area

φ20-φ200mm,length:6000mm

Positioning accuracy

±0.03mm

Load-bearing

150KG

Processing area

6000*2000mm

Pipe processing area

φ20-φ200mm,length:6000mm

Positioning accuracy

±0.03mm

Load-bearing

150KG

Processing area

6000*2500mm

Pipe processing area

φ20-φ200mm,length:6000mm

Positioning accuracy

±0.03mm

Load-bearing

150KG

Processing area

3000*1500mm

Pipe processing area

φ20-φ200mm,length:6000mm

Positioning accuracy

±0.03mm

Load-bearing

150KG

Processing area

6000*2000mm

Pipe processing area

φ20-φ200mm,length:6000mm

Positioning accuracy

±0.03mm

Load-bearing

150KG

You will receive a response within one business day